Sustainability in the hospital – An investment in the future

Definition of sustainability and its importance for the health sector

For us, sustainability means protecting our environment while ensuring the health and well-being of all people.

This concept holds particular relevance in hospitals, where daily use of finite resources – from medical devices to protective clothing – is unavoidable. Simultaneously, the healthcare system is poised to encounter significant challenges in the upcoming years:

Firstly, there is a global increase in population, leading to a surge in hospital stays.

Secondly, the demands for treatment and care are continously increasing, resulting in a substantial rise in resource consumption across the health sector – spanning from medicines to energy to waste.

Given these circumstances, it becomes imperative to prioritize sustainability in hospitals and to develop solutions for environmentally friendly and resource-efficient healthcare.

Experts estimate that waste reduction and energy-saving measures within hospitals can potentially cut between 15% and 50% of carbon dioxide (CO2e) emissions. The measures in achieving this lies in the behavior of hospital staff.

Here’s where Vanguard becomes a game-changer

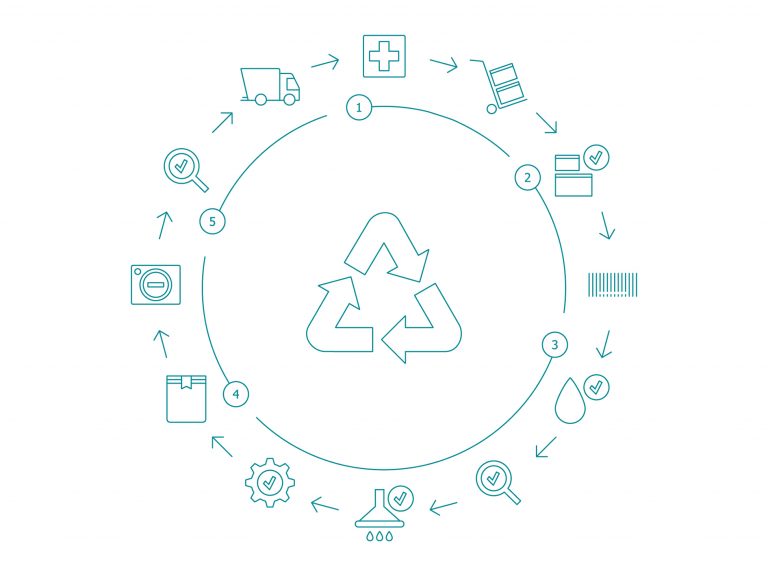

We extend the product life cycle of single-use medical devices, facilitating a circular economy in healthcare facilities. In comparison to manufacturing a new catheter, we can reduce the carbon footprint of a Catheter by over 50% by simply remanufacturing it, firmly integrating Vanguard AG remanufacturing business model as a decarbonization measure across the healthcare supply chain.

It’s noteworthy that the health sector contributes more greenhouse gases than aviation and shipping combined.

The health sector produces more greenhouse gases than aviation and shipping.

5%

of German raw material consumption is accounted for by the health sector.

4.4%

The health sector is responsible for 4.4% of global greenhouse gas production.

2 GT

Global emissions from the health sector are equivalent to two gigatonnes of CO2e.

514 KKW

The annual greenhouse gas emissions of the global health sector are equivalent to the amount of 514 coal-fired power plants.

71%

of the emissions generated by the health sector are primarily caused by its supply chains.

Societal expectations for a resource-conserving and climate-friendly economy have instigated a profound transformation in the healthcare sector. Sustainability and energy conservation are not just fleeting government initiatives but are emerging as central economic success criteria for the future.

Overview of Climate Protection Measures in Hospitals:

Hospitals face the challenge of reducing energy consumption and waste while maintaining economic viability. This necessitates a shift in the procedures and processes of daily operations.

A study reveals that:

71% of surveyed hospitals incorporate climate protection into their climate change adaptation strategy.

38% have established guidelines and targets for energy efficiency and sustainability.

30% address these issues through a designated climate manager.

Several established and applied individual measures include:

68% regularly record and monitor their consumption figures.

80% employ shading techniques to prevent heat build-up (e.g., using building structures, trees, or blinds).

74% have installed heat-insulating windows.

Waste separation plays an important role:

70% of hospitals have developed concepts for waste separation.

75% are already mindful of reducing packaging waste during product procurement.

Less waste by reprocessing disposable products in hospitals – a convincing solution:

Anyone who has glimpsed behind the scenes in a hospital knows that the volume of waste generated is substantial. German hospitals produce approximately five to six kilograms of waste per hospital bed every day. This includes disposable medical products or non-infectious waste, which hospitals must dispose of in a time-consuming and costly manner.

The cost of disposing of medical waste in a maximum-care hospital is about 800 € per hospital bed per year. To counteract waste generation, hospitals prioritize the primary goal of waste avoidance. This can be achieved, among other perks, through the circular use of a remanufactured cartheter by Vanguard AG.

Our mission

Vanguard AG has set itself the goal of enabling the circular economy in hospitals for innovative medical devices. This goal stems from the recognition that responsible use of valuable raw materials in manufacturing and utilizing complex medical devices is crucial for ecologically and economically sustainable medical care. At Vanguard AG, sustainability, energy conservation, and environmental protection are not just principles but integral to our operations.

We implemented remote work options even before the onset of the Corona pandemic, and actively encourage our employees to embrace video conferencing to minimize car journeys. Our recent involvement in the “Klimaretter-Lebensretter” (Climate Savers-Lifesavers) project by viamedica – Stiftung für eine gesunde Medizin (Foundation for Healthy Medicine) underscores our dedication to sensitizing healthcare workers to the prudent use of energy and resources.

Our solution

As an innovative medical remanufacturer, we play a significant role by fostering a shift from the linear consumption of single-use medical devices to a circular-consumption model while adhering to the highest quality and safety standards. Through our pioneering and certified medical remanufacturing processes, we extend the life cycle of single-use medical devices. This facilitates a circular economy in medical facilities such as clinics and hospitals, promoting more sustainable and future-oriented operations.

Our sustainable business model reduces the demand for new products in clinical settings, minimizes the disposal of environmentally harmful clinical hazardous waste, and thereby safeguards the environment, its natural resources, and the climate. Additionally, our activities contribute to shortening the supply chain by cutting off raw material transportation across regions, from developing countries to the original equipment manufacturers. Consequently, we can claim a more than 50% reduction in the carbon footprint of a remanufactured catheter compared to its new production.

Contact us directly in a quest for partenership for goals, have Vanguard AG as your decarbonization partner and let’s collaborate to optimize your carbon footprint through Medical Remanufacturing for long-term sustainability.

Vanguard AG: The Sustainable Choice

In a groundbreaking study, Fraunhofer UMSICHT compared the environmental impact of a newly produced catheter with that of a catheter remanufactured by Vanguard AG. Their impact on global warming and abiotic resource consumptions were also taken into account.